Since 1998 the company Arredi Sacri Memeo has a relevant place into the market of religious articles for church and in the production of sacred furniture with its own line of religious articles completely Made in Italy and Nickel Free, taking care of the creation, production and distribution of the model by their own. Twenty years of experience combined with the ability to grasp the changes of artistic trends and tastes of our customers, we show in the entire production of our workshop.

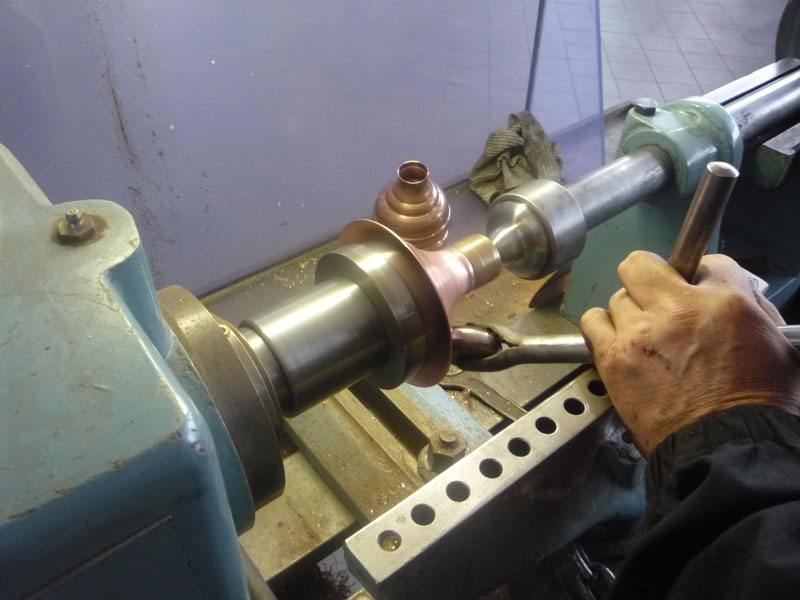

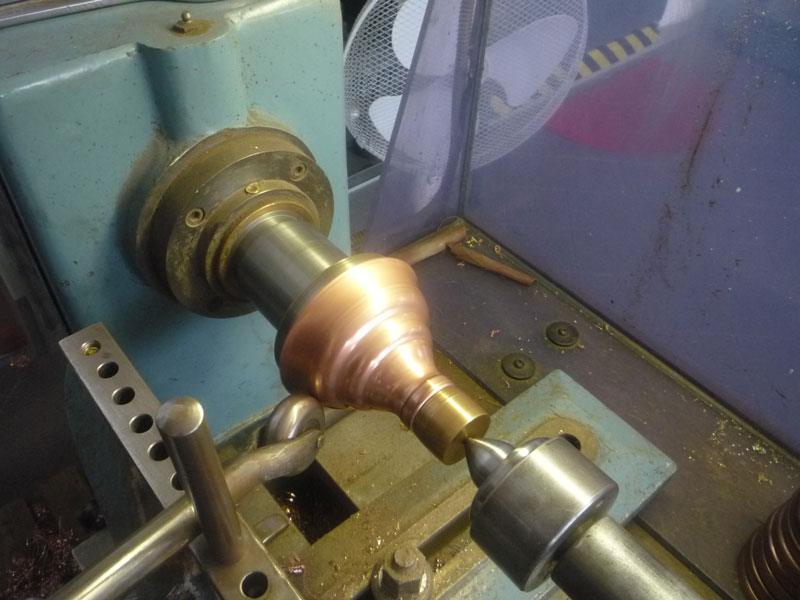

Manual mastery in creating sophisticated and sometimes unique pieces, while the acquired experience allows us to repair and restore pieces of priceless historical and artistic value.

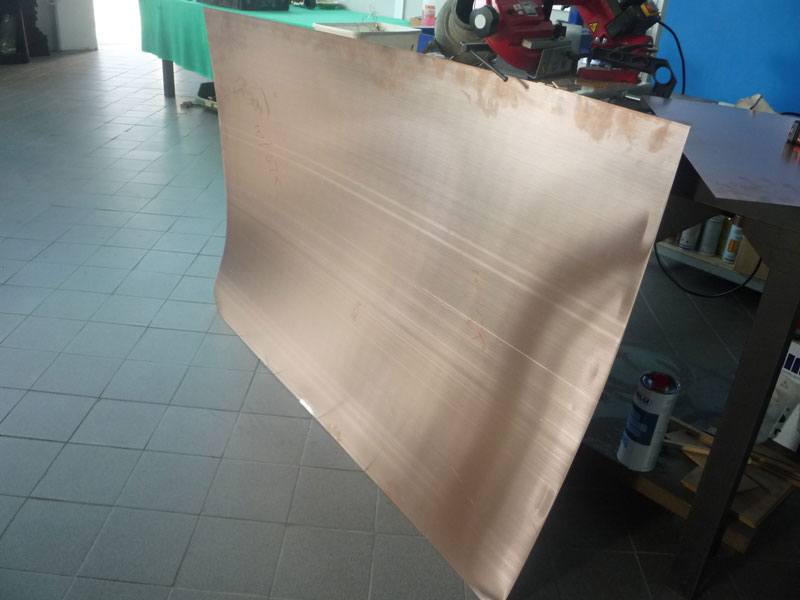

Arredi Sacri Memeo chose raw material of first class; the machining and finishing of each article, show the union of craftsmanship and skill of the craftsmen with the support of precision and innovation of new technologies ensuring accuracy,precision and beauty over time.

Laboratory and showroom

By 2016 we moved into our new home, both legal and productive department. The new lab permitted to make improvements in the company’s artistic process with the inclusion of plant and equipment of the latest generation that are improving and speeding up the process chain. The artistic line of Arredi Sacri Memeo shows in its models the smooth lines and simple elegance and sophistication, in other articles the movement and the magnificence of the Baroque style, to complete the offer with chiseled models by skilled craftsmen of experience and great skill.

PRODUCTIVE PROCESS

Our products are born from our design, we realized with the help of art professionals, trying to follow the tastes and the information provided by our customers.

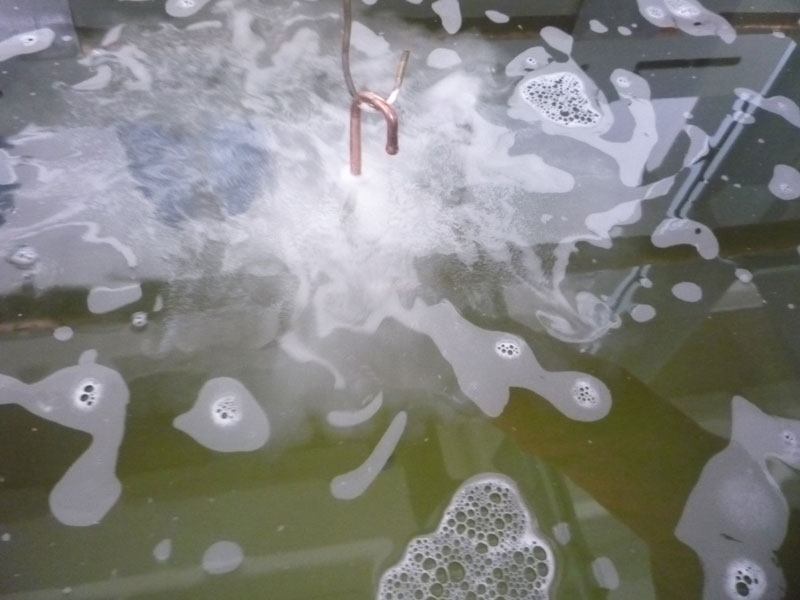

Our articles come from our design, made with the help of art professionals, trying to follow the tastes and the guidance provided by our customers. The piece can be realized by the foundry or directly from the slab. After the melting step, it is assembled as it would be by project. Subsequently it is again divided into pieces to undergo the blasting treatment and, then, the cleaning. The gold or silver platting, is achieved thanks to the internal galvanic process of our company. The final step consists in protection painting, which is fixed thanks to the passage in a specific oven, and the final stage with the final assembly of the product. The transparent coating is a peculiar step in our production, because it will help to save the gold / silver finishing of the product (made on the smooth parts), ensuring greater protection from wear, human sweat which is not cleaned immediately, from temperature changes in aviation transport or weathering a humid climate of customer’s living place.

NICKEL FREE

All our products are Nickel Free. What does Nickel Free mean? For Nickel Free we generally mean objects or materials in which there is no trace of nickel. Nowadays, particular attention is paid to the topic given the possibility (in truth rather rare) to show allergies to this material. In March 2013, a regulation was introduced to regulate the market: the manufacture and / or placing on the market of objects having a nickel release higher than the allowed limit is prohibited. The use of Nickel makes a film on the product in order to limit the quantity of gold/silver micron.

RULE

Starting from March 31, 2013, the introduction on the market of products that do not meet the nickel release limits set by the REACH Regulation is prohibited. Please note that the restriction indicated in Regulation 1907/2006 REACH concerns any product intended for direct or prolonged contact with the skin or intended to be inserted into perforated parts of the human body (earrings or piercings) without any distinction regarding the material with the which is constituted. The use of nickel-containing alloys for these products should therefore be assessed. By way of example, it should be noted that use of such alloys is widespread in white gold alloys for any legal title while it is difficult to apply in silver alloys, since the use of nickel in intermediate galvanic coatings has long been abandoned.